Quality Genuine parts from CUMMINS.

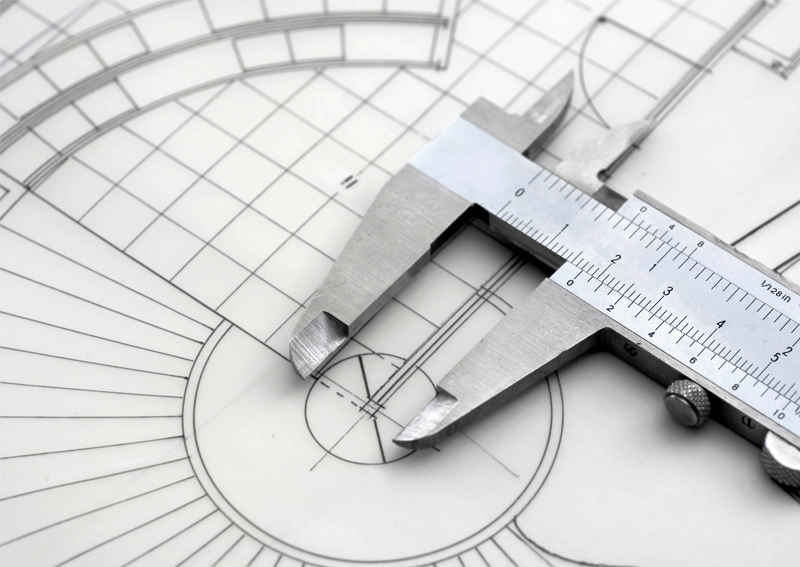

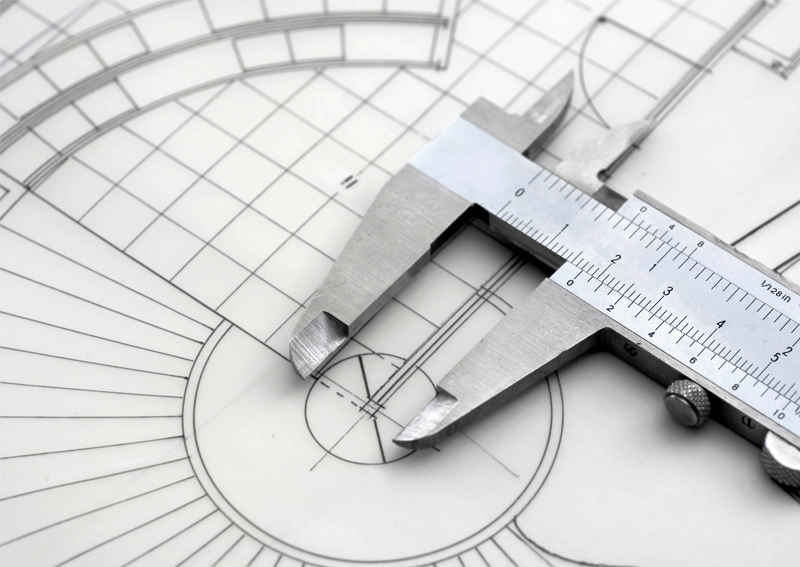

Many competitive part manufacturers try to reverse-engineer Cummins parts and build something that fits like an original part at a cheaper price. The problem is, these will-fit parts don’t meet critical specifications from either a dimensional or materials standpoint. When it comes to performance fuel economy, reliability and durability, microns matter and so do the metals used in your components. The potential cost factors rise in direct proportion to the size of the engine and the loss of equipment efficiency. The operation of equipment in remote regions can result in logistical challenges that add significant costs and impact productivity. Genuine Cummins Parts provide unmatched quality to ensure that your operation keeps running in a world that’s Always On

Buying a genuine Cummins part, gets you more value with less downtime and less risk of failure.

Sometimes it can be hard to see the difference between Genuine Cummins Parts and non-genuine parts. Non-genuine parts may fit a Cummins Product, but they aren’t built or re-manufactured using the same procedures or materials to Cummins’s exact specifications.

Relying on Genuine Cummins Parts is the best way to ensure the long life of your engine. Here’s why:

Leave All Doubt at the LAB.

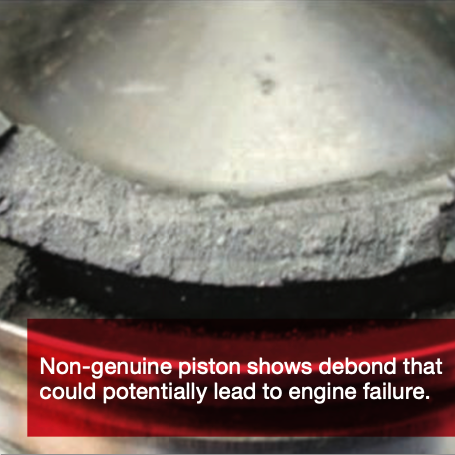

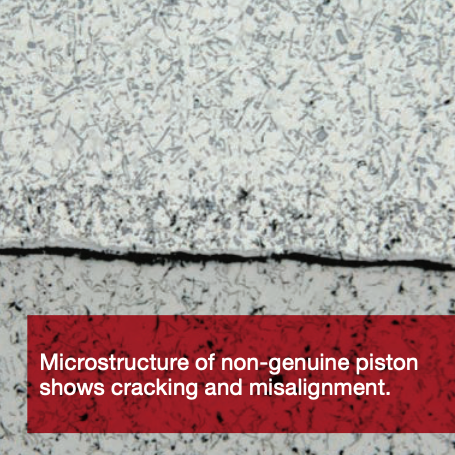

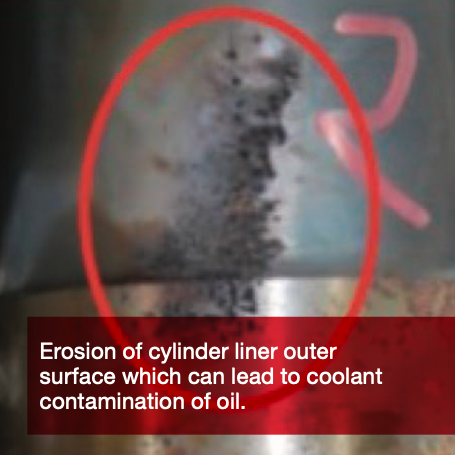

Recently, Cummins tested 237 non-genuine components for 19L and above engines including pistons, rings, valves, cylinder liners, connecting rods and pins, as well as even smaller items such as springs and retaining clips. The results were eye-opening, to say the least. Of the 237 parts tested, not a single component met Cummins specifications.

Cummins has tested over 237 non-genuine components including pistons, rings, valves, cylinder liners, connecting rods, and pins, as well as even smaller items such as springs and retaining clips. The results were eye-opening, to say the least. Follow this series as we break down the difference.

Many competitive parts manufacturers try to reverse engineer Cummins parts and build something reasonably close at a cheaper price. The problem is, that these non-genuine parts usually don’t meet critical specifications either dimensionally or from a materials standpoint.

Today non-genuine parts suppliers develop parts that they think will fit your Cummins engine. While the initial savings can be enticing, oftentimes there are differences compared to the Genuine Cummins QSK part that you may or may not be able to see with the naked eye. Your genuine part will perform the same or better than the original.

In a recent study, we compared Genuine Cummins DPFs to will-fit DPFs in vehicles equipped with 2007 ISX15 engines, under real-world operating conditions. The difference in performance was staggering.

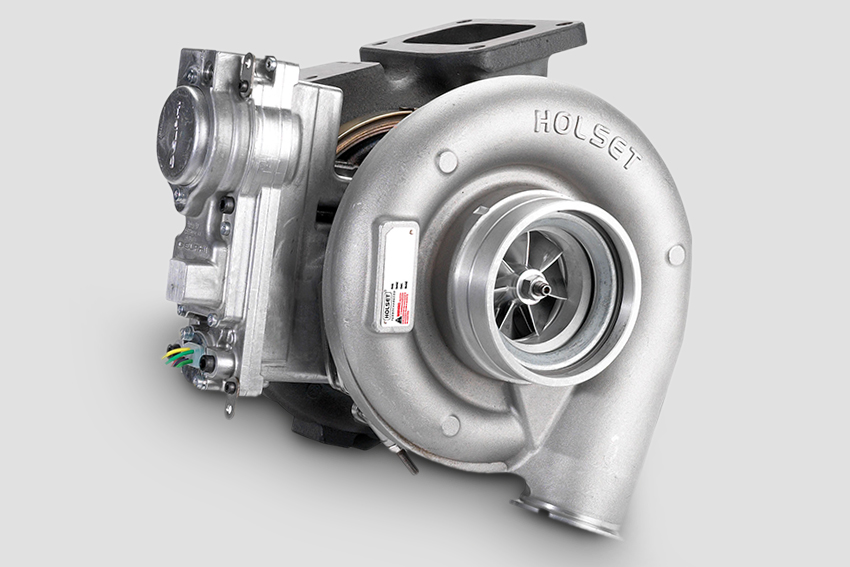

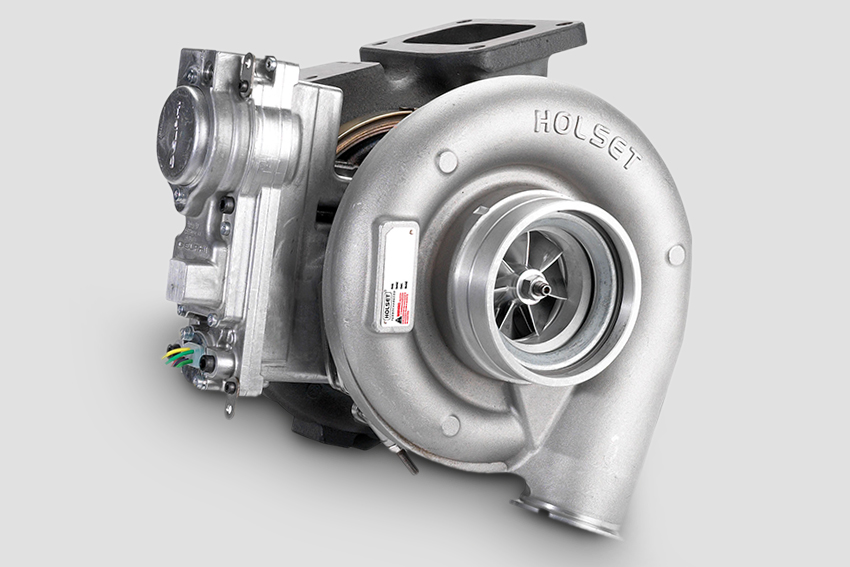

The right Holset turbocharger replacement means less downtime, better power performance, and better fuel economy for years to come. We put Holset to the test to prove the risks of will-fit, rebuilt, repaired, or remanufactured turbos. Don’t gamble by using non-genuine turbochargers.

Cummins has tested over 237 non-genuine components including pistons, rings, valves, cylinder liners, connecting rods, and pins, as well as even smaller items such as springs and retaining clips. The results were eye-opening, to say the least. Follow this series as we break down the difference.

Many competitive parts manufacturers try to reverse engineer Cummins parts and build something reasonably close at a cheaper price. The problem is, that these non-genuine parts usually don’t meet critical specifications either dimensionally or from a materials standpoint.

Today non-genuine parts suppliers develop parts that they think will fit your Cummins engine. While the initial savings can be enticing, oftentimes there are differences compared to the Genuine Cummins QSK part that you may or may not be able to see with the naked eye. Your genuine part will perform the same or better than the original.

In a recent study, we compared Genuine Cummins DPFs to will-fit DPFs in vehicles equipped with 2007 ISX15 engines, under real-world operating conditions. The difference in performance was staggering.

The right Holset turbocharger replacement means less downtime, better power performance, and better fuel economy for years to come. We put Holset to the test to prove the risks of will-fit, rebuilt, repaired, or remanufactured turbos. Don’t gamble by using non-genuine turbochargers.

Cummins has tested over 237 non-genuine components including pistons, rings, valves, cylinder liners, connecting rods, and pins, as well as even smaller items such as springs and retaining clips. The results were eye-opening, to say the least. Follow this series as we break down the difference.

Many competitive parts manufacturers try to reverse engineer Cummins parts and build something reasonably close at a cheaper price. The problem is, that these non-genuine parts usually don’t meet critical specifications either dimensionally or from a materials standpoint.

Today non-genuine parts suppliers develop parts that they think will fit your Cummins engine. While the initial savings can be enticing, oftentimes there are differences compared to the Genuine Cummins QSK part that you may or may not be able to see with the naked eye. Your genuine part will perform the same or better than the original.

Σε μια πρόσφατη μελέτη, συγκρίναμε τα γνήσια DPF της Cummins με μη γνήσια, σε οχήματα εξοπλισμένα με κινητήρες ISX15 του 2007, υπό πραγματικές συνθήκες λειτουργίας. Η διαφορά στην απόδοση ήταν εκπληκτική.

The right Holset turbocharger replacement means less downtime, better power performance, and better fuel economy for years to come. We put Holset to the test to prove the risks of will-fit, rebuilt, repaired, or remanufactured turbos. Don’t gamble by using non-genuine turbochargers.

Here, part by part, are specific examples of the quality issues in materials, design and manufacturing as well as the probable problems that would result.

Using non-genuine parts does more than compromise the performance of your high-horsepower engine. It jeopardizes your business and makes it hard to meet customer expectations. The miniscule amount you save upfront using non-genuine parts down the road. When your profitability and reputation count on it, use Genuine Cummins Parts to assure continuous performance in a world that’s Always On.

The results from the lab show there’s a significant risk to using non-genuine parts. But the real cost of buying a cheaper will-fit components is the business cost that you incur from lost productivity due to equipment downtime and decreased performance. These include increased operating costs from using more fuel due to compromised combustion, productivity losses when power output is diminished and cycle times increase. Then there’s the cost of downtime. You ‘re going to spend significantly more on parts and labor to repair your engine, plus you are going to lose hours and potentially days of production. Whether it’s an excavator in a mine, a train blocking an important trunk line or an entire building losing electrical power, it’s a disruption you can’t afford in a world that’s Always On.

Not to mention the reduction in resale value when you go to sell that piece of equipment and the prospective buyer looks at its maintenance record.

Using non-genuine parts does more than compromise the performance of your high-horsepower engine. It jeopardizes your business and makes it hard to meet customer expectations. Genuine Cummins Parts come with a manufacturer’s warranty, ensuring financial protection and peace of mind. The amount you save upfront using non‑genuine parts is likely to cost you a lot more further down the road. When your profitability and reputation count on it, use Genuine Cummins Parts to ensure continuous performance in a world that’s Always On.

Genuine Cummins parts provide you with a cost-effective, environmentally friendly, no-surprise solution that quickly puts your Cummins powered equipment back to work.

| Part | Issue | Damage| Performance Ipact |

|---|---|---|

|

Pistons |

Shallow ring grooves | Ring breakage, high oil consumption, blowby, scuffing |

| Out-of-spec bowl dimentions | Excess heat, cracking, high fuel consumption, visible smoke | |

| Debonding of rings carriers | Catastrophic engine failure | |

|

Piston Rings |

Out-of-spec ring angles | Insufficient sealing, excess fuel usage, decreased performance |

| Incorrect size of oil ring (too thick) | Poor oil scraping, excessive oil consumption | |

| Incorrect size of top ring (too thin) | Excess rotation, poor sealing, increased blowby | |

|

Piston Pins |

Missing from some kits | Repair delays, downtime, extra cost |

| Out-of-spec outer diameters | Incorrect fit issues, repair delays | |

| Intergranular oxidation | Manufacturing defect, increased potential for premature fatigue and cracking | |

|

Cylinder Liners |

Oversize outer diameters | Radial stress leading to metal fatigue |

| Insufficient lower outer diameters | Liner rocking and fretting | |

| Oversize inner diameters | Cavitation leading to pitting, coolant leaks and mission-disabling failure | |

| Improper cross-hatching | Compromised lubrication, increased wear, higher blowby and oil consumption, decreased service life | |

| Excess crystals in liner coating | Poor coating adhesion | |

| Insufficient metal strength | Premature wear, potential failure | |

|

Valve Springs |

Below spec for hardness | Degraded performance over time |

| Insufficient heigh load | Improper seating resulting in combustion leaks and premature wear-out of valve seat inserts | |

| Valve Seat Inserts | Runout does not meet specifications, can’t square to seat | Increased wear, combustion leakage, potential valve failure |

|

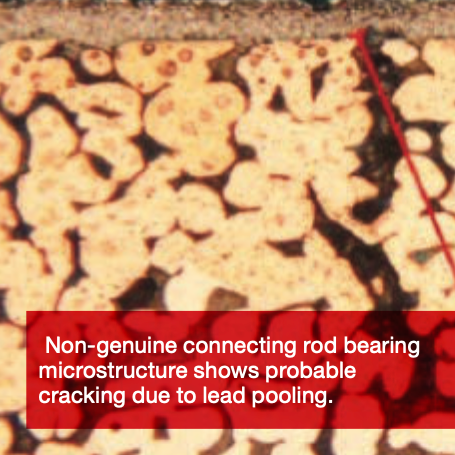

Connecting Rod Bearings |

Tangs too narrow | Interference issues, misalignment of oil holes hindering oil flow |

| Metals sintered, not cast | Lower corrosion resistance | |

| Excess lead pooling | Fatigue cracking | |

| Connecting Rod Bushings | Excess lead in lining layer | Delamination and cracking |

Sales: Mon-Fri 09:00-17:00

Parts: Mon-Fri 08:00-16:00

Service: Mon-Fri 08:00-16:00

ATHENS

Thesi Patima,

196 00 Mandra Attiki

tel: 210 62 93 400,

210 62 93 412

email: ergotrak@ergotrak.gr

THESSALONIKI

VIPE Sindos, Phase G, block.32 ΝΒ1Α Str, 570 22 Thessaloniki Tel: 2310570070

email: ergotrak@ergotrak.gr

ATHENS BRANCH

173 Athinon Av., 122 42 Egaleo

tel: 2105783070

email: ergotrak@ergotrak.gr

Powered by Simio